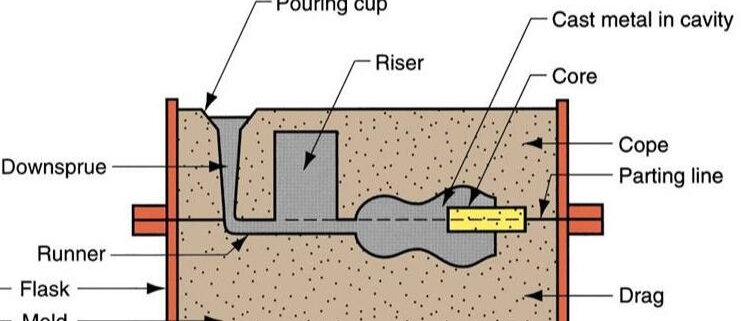

The gating system depends on the direction of the parting plane, which contains the sprue, runner and the ingate. They are as follows:

Horizontal Gating System : This is used most widely. This type is normally applied in ferrous metal’s sand casting and gravity die-casting of non-ferrous metals. They are used for flat casting, which are filled under gravity.

Vertical Gating System: This is applied in tall castings were high-pressure sand mold, shell mold, and die-casting processes are done. Top Gating System: this is applied in places where the hot metal is poured from the top of the casting. It helps directional solidification of the casting from top to bottom. It suits only flat castings to limit the damage of the metal during the initial filling.

Bottom Gating System : it is used in tall castings where the molten metal enters the casting through the bottom.

Middle Gating System : It has the characteristics of both the top and bottom.