Advantages of HuaGuang’s Exothermic Insulating Riser Sleeves

The solidification time is 2.55-2.9 times longer than that of the sand riser, the molten metal used for feeding is reduced by 50-70%, and the product yield is increased by 25-30%. When the processing technology is used on the top riser, the contact area between the riser and the castings is reduced. Compared with the ordinary sand riser, the cutting and grinding areas are reduced by 60-70%, which greatly reduces the fettling costs, thereby reducing the production costs.

The use of the exothermic insulating riser shall eliminate the shrinkage defects that can’t be overcome by sand risers. Using automatic molding lines ensures the production of stable castings. Due to its exothermic properties, it can be used on cold risers to simplify runner systems, which is particularly beneficial for ductile iron parts.

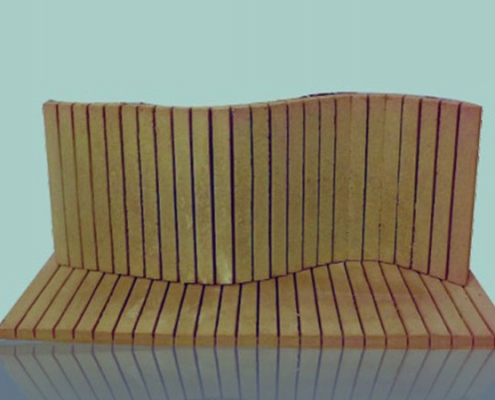

Characteristics

Compared with the ordinary sand riser, the strength of the riser is increased by 50-70%. Advantages such as Less damage during modeling, good air permeability, uniform riser sleeve wall thickness and a V-shaped cone on the top of blind riser shall improve the heat insulation and feeding effect, and at the same time make the riser sleeve heat and thermal insulation properties and physical properties more stable.

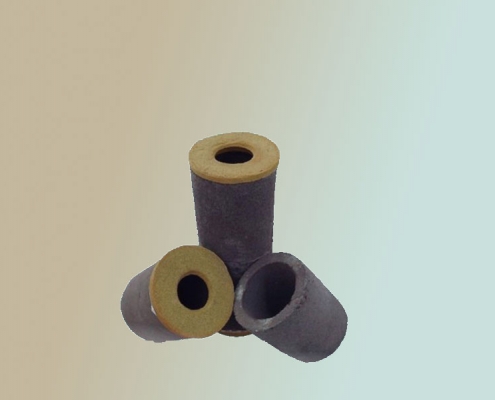

Fiber composite insulating riser sleeve

The main features of the Fiber Composite Insulating Riser Sleeve are lightweight, high fire-resistant, small high-temperature linear shrinkage, high show porosity, small heat loss rate, and good thermal insulation performance. After use, not only the shrinkage and dispersed shrinkage inside the casting are eliminated, and the quality of the casting is improved, but also the efficiency of the riser feeding is significantly increased, the amount of molten steel in the riser is reduced, the actual yield of the casting is increased and the cost is decreased. It has been widely used in castings including cast steel, cast iron, and non-ferrous alloys, etc.