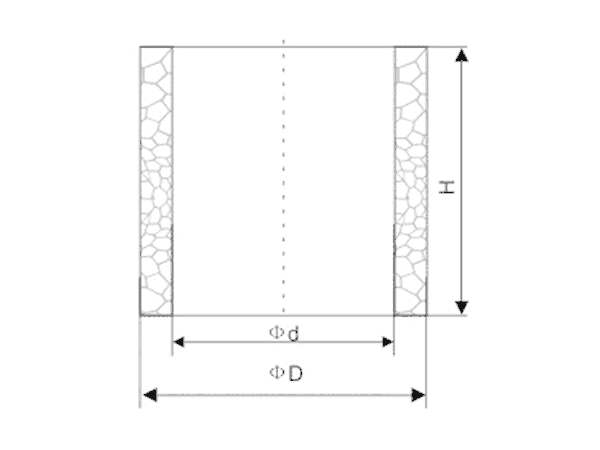

Exothermic Insulating Riser Sleeve-cylindrical/straight

Highly insulating and exothermic feeder sleeve for iron and steel castings.

The exothermic riser sleeves are manufactured with quality materials and engineered for maximum performance and safety with minimum risk. It offers three levels of exothermic riser sleeves: a mild exothermic sleeve for when the metal needs to stay liquid longer, and a high exothermic product that adds heat to the metal for better feeding efficiency. Exochem also offers an exothermic sleeve for manganese steel.

The Riser sleeve product with its low density, high strength, and good toughness is suitable for various grades of cast steel, cast iron, and alloy castings, as well as various molding processes.

We offer many types of insulating and exothermic riser sleeve formulations and geometries to meet your specific metal type, modulus requirements, molding application and riser removal needs. Exothermic hot toppings, riser covers and exothermic cores help to maximize the feeding performance of your risers.

Overview of Exothermic Insulating Riser Sleeve

The product adopts new materials such as exothermic agent, insulation materials and binder to develop high-efficiency Exothermic Insulating Riser Sleeves.

Our Exothermic Insulating Riser Sleeves according to different shapes are divided into oval, neck-down, cylindrical, side type, flexible board and core-shot sleeves (Mainly used for small to medium iron and steel castings)

Cylindrical, neck-down and side sleeves shall also be provided with riser caps because you may choose the type of risers as you need: open riser or blind riser.

With low density and precise dimensions, core-shot sleeves(AN series) can be used in various ferrous and non-ferrous metal castings. And it can be set on the molding plate or embedded in the mould after molding.

Heating mechanism

The exothermic insulating riser sleeves adopt high-quality insulation material and high-efficiency exothermic agent. The rapid cooling effect is very small. Once the molten steel is injected into the riser sleeve, the heating reaction is excited, and the riser sleeve will heat it greatly. After the heating reaction ends, the riser sleeve insulation material begins to work, ensuring that the solidification time of the molten metal in the riser is effectively extended.It has the functions of heat insulation at first, generating heat in the middle, and heat preservation for a long time at the end to achieve the best feeding effect.

Specification of ZT-Series Cylindrical Riser Sleeves

| No. | Specification

(d×h) |

Effective Module

(cm) |

Geometric Module

(cm) |

Boundary Dimension (cm) | Volume(ml) | ||

| d | D | H | |||||

| ZT01 | Φ90×120 | 2.15 | 1.50 | 90 | 120 | 120 | 399 |

| ZT02 | Φ100×125 | 2.50 | 1.75 | 100 | 130 | 125 | 481 |

| ZT03 | Φ110×140 | 2.86 | 2.00 | 110 | 140 | 140 | 703 |

| ZT04 | Φ120×145 | 3.15 | 2.20 | 120 | 155 | 145 | 881 |

| ZT05 | Φ130×155 | 3.51 | 2.54 | 130 | 165 | 155 | 1282 |

| ZT06 | Φ140×140 | 3.86 | 2.70 | 140 | 175 | 140 | 1602 |

| ZT1 | Φ150×150 | 3.58 | 2.50 | 150 | 195 | 150 | 2649 |

| ZT2 | Φ180×180 | 4.29 | 3.00 | 180 | 230 | 180 | 4578 |

| ZT3 | Φ200×200 | 4.77 | 3.33 | 200 | 250 | 200 | 6280 |

| ZT4 | Φ225×225 | 5.36 | 3.75 | 225 | 275 | 225 | 8942 |

| ZT5 | Φ250×250 | 6.04 | 4.17 | 250 | 305 | 250 | 12266 |

| ZT6 | Φ275×275 | 6.65 | 4.58 | 275 | 330 | 275 | 16326 |

| ZT7 | Φ300×300 | 7.25 | 5.00 | 300 | 360 | 300 | 21195 |

| ZT8 | Φ325×163 | 5.90 | 4.07 | 325 | 385 | 163 | 13515 |

| ZT9 | Φ325×325 | 7.85 | 5.42 | 325 | 385 | 325 | 26948 |

| ZT10 | Φ350×175 | 6.13 | 4.38 | 350 | 415 | 175 | 16828 |

| ZT11 | Φ350×350 | 8.17 | 5.85 | 350 | 415 | 350 | 33657 |

| ZT12 | Φ375×188 | 6.57 | 4.69 | 375 | 440 | 188 | 20753 |

| ZT13 | Φ375×375 | 8.75 | 6.25 | 375 | 440 | 375 | 41396 |

| ZT14 | Φ400×200 | 7.00 | 5.00 | 400 | 465 | 200 | 25120 |

| ZT15 | Φ400×400 | 9.33 | 6.67 | 400 | 465 | 400 | 50240 |

| ZT16 | Φ450×150 | 6.21 | 4.50 | 450 | 515 | 150 | 23844 |

| ZT17 | Φ450×300 | 8.87 | 6.43 | 450 | 515 | 300 | 47689 |

| ZT18 | Φ450×450 | 10.35 | 7.50 | 450 | 515 | 450 | 71553 |

| ZT19 | Φ500×167 | 6.71 | 5.01 | 500 | 565 | 167 | 32774 |

| ZT20 | Φ500×334 | 9.58 | 7.15 | 500 | 565 | 334 | 65548 |

| ZT21 | Φ500×500 | 11.17 | 8.33 | 500 | 565 | 500 | 98123 |

| ZT22 | Φ500×184 | 7.28 | 5.51 | 550 | 620 | 184 | 43693 |

| ZT23 | Φ550×368 | 10.39 | 7.87 | 550 | 620 | 368 | 87386 |

| ZT24 | Φ550×550 | 12.10 | 9.17 | 550 | 620 | 550 | 130604 |

| ZT25 | Φ600×200 | 7.80 | 6.00 | 600 | 670 | 200 | 56520 |

| ZT26 | Φ600×400 | 11.14 | 8.57 | 600 | 670 | 400 | 113040 |

| ZT27 | Φ600×600 | 13.0 | 10.00 | 600 | 670 | 600 | 169560 |

Advantages of HuaGuang’s Exothermic Insulating Riser Sleeves

The solidification time is 2.55-2.9 times longer than that of the sand riser, the molten metal used for feeding is reduced by 50-70%, and the product yield is increased by 25-30%. When the processing technology is used on the top riser, the contact area between the riser and the castings is reduced. Compared with the ordinary sand riser, the cutting and grinding areas are reduced by 60-70%, which greatly reduces the fettling costs, thereby reducing the production costs.

The use of the exothermic insulating riser shall eliminate the shrinkage defects that can’t be overcome by sand risers. Using automatic molding lines ensures the production of stable castings. Due to its exothermic properties, it can be used on cold risers to simplify runner systems, which is particularly beneficial for ductile iron parts.

Characteristics

Compared with the ordinary sand riser, the strength of the riser is increased by 50-70%. Advantages such as Less damage during modeling, good air permeability, uniform riser sleeve wall thickness and a V-shaped cone on the top of blind riser shall improve the heat insulation and feeding effect, and at the same time make the riser sleeve heat and thermal insulation properties and physical properties more stable.

Fiber composite insulating riser sleeve

The main features of the Fiber Composite Insulating Riser Sleeve are lightweight, high fire-resistant, small high-temperature linear shrinkage, high show porosity, small heat loss rate, and good thermal insulation performance. After use, not only the shrinkage and dispersed shrinkage inside the casting are eliminated, and the quality of the casting is improved, but also the efficiency of the riser feeding is significantly increased, the amount of molten steel in the riser is reduced, the actual yield of the casting is increased and the cost is decreased. It has been widely used in castings including cast steel, cast iron, and non-ferrous alloys, etc.