Advantages of HuaGuang’s Ceramic products for foundry pouring system:

- The high density of the ceramic tube for casting greatly reduces the secondary oxidation of the molten steel in the pouring process and reduces the inclusion of objects into the casting body.

- The inner surface is smooth with small resistance, so the molten steel has fast speed, which can effectively reduce all kinds of resistance, such as to receive gating system for casting, casting sand core and the casting structure itself, which can also reduce thermal cracking caused by heat stress within the castings.

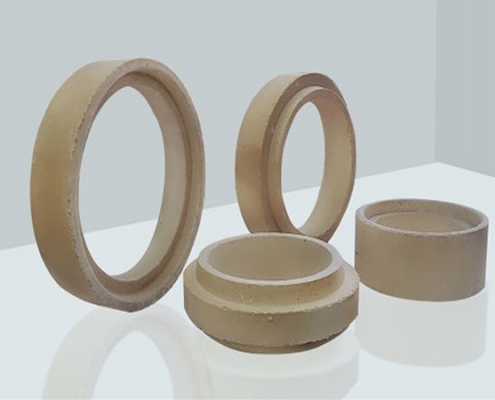

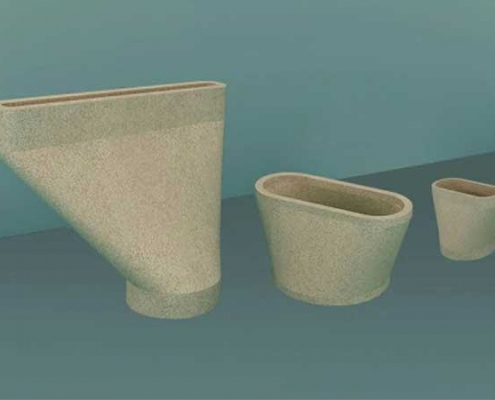

- This ceramic tube has high refractoriness (>1700 ℃ ), abrasion resistance, convenient to use, can connect to a straight pipe, elbow, adapter bonnet, three-branch pipe, five-way pipe and the variable diameter gate with the adhesive tape freely as you want. When you use this ceramic tube in the gating system, there is no need to use the coating or painting and runner bricks, so it can reduce your cost.

- The corrosion resistance of Huaguang’s ceramic tube is superior to runner brick greatly. Compare with runner brick, Ceramic tube generates low waste, convenient to clean. It also can improve the utilization rate of the sand, and save time and labor.

- The tube also has good chemical stability, it won’t cause a chemical reaction with metal liquid(molten steel or molten iron) under high temperature. After pouring, the surface of the pouring channel is smooth, and the pouring process is free of corrosion.

- The tube has high thermal strength, good thermal plastic. It can effectively prevent sand washing or inclusion, and reduce the defects of the casting sand holes. The thermal expansion coefficient is low, and the shrinkage effect of casting is small, which reduces the cracking phenomenon in the gating system.