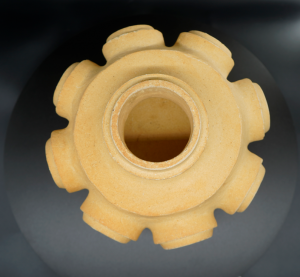

This product is suitable for resin sand, sodium silicate sand, and some other formative technology. It is used for casting high manganese steel, alloy steel, stainless steel, carbon steel, high chromium cast iron, ductile iron, grey iron castings, etc.

1.The high density of the ceramic tube for casting greatly reduces the secondary oxidation of the molten steel in the pouring process, and reduces the inclusion of objects into the casting body.

2.It has high refractoriness (>1700 ℃ ), abrasion resistance, convenient to use.

- The corrosion resistance of the Ceramic tube is superior to runner brick greatly. The sprue tube also has good chemical stability, it won’t cause chemical reaction with metal liquid(molten steel or molten iron) under high temperature. Compare with runner brick, ceramic tube generate low waste, convenient to clean .It also can improve the utilization rate of the sand, and save time and labor.

- The tube has high thermal strength, good thermal plastic. It can effectively prevent sand washing or inclusion , and reduce the defects of the casting sand holes. The thermal expansion coefficient is low, and the shrinkage effect of casting is small , which reduce the cracking phenomenon in gating system.