HG-AN series exothermic Insulation Riser Sleeves.

With low density and precise dimensions, AN series small riser sleeve can be used in various ferrous and non-ferrous metal castings pouring system. And it can be set on the molding plate or embedded in the sand mold after modeling.

Compare with other risers, AN series have more heat flux.

We offer riser cover for the straight one, necking downs and oblique riser. It is convenient for you to choose open riser or closed one. It has low density, high strength and toughness, which suit for all kinds of casting.

Heat mechanism:

The exothermic insulation riser has adopted good insulation material and high efficient exothermic. There are little quenching effect, once the liquid steel was pour into the riser, the exothermic reaction will be activated, then the riser will heat the liquid steel with it’s fever, after the reaction, the insulation material will ensure the coagulation time of the liquid steel. The best feeding efficiency comes from the characters: Initial adiabatic, then fever, heat preservation for a long time in the end.

These riser sleeves provide the foundry with a reliable cost-effective approach for optimizing feeding efficiency, improving quality, and lower costs.

Advantages:

The solidification time is 2.55-2.9 times longer than that of the sand riser, the molten metal used for feeding is reduced by 50-70%, and the product yield is increased by 25-30%. When the processing technology is used on the top riser, the contact area between the riser and the castings is reduced. Compared with the ordinary sand riser, the cutting and grinding area is reduced by 60-70%, which greatly reduces the fettling costs, thereby reducing the production costs.

The use of the exothermic insulating riser shall eliminate the shrinkage defects that can’t be overcome by sand risers. Using on automatic molding lines ensures the production of stable castings. Due to its exothermic properties, it can be used on cold risers to simplify runner systems, which is particularly beneficial for ductile iron parts.

The features of the exothermic insulation riser:

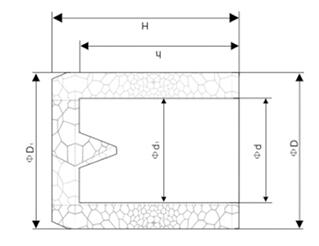

The strength of this riser increases 50-70% than the common sand riser. There is little damage during molding and the air permeability is quite good, the thickness of the riser wall is equality, by the way, there is the V shape centrum on the top of the closed riser can improve the adiabatic and feeding effect, also, it can make the heat insulation performance and physical performance of the riser head more stable at the same time.

| No. | Specification

(d×d1×H) |

Effective Module

(cm) |

Geometric Module

(cm) |

Boundary Dimension (cm) | Volume(ml) | |||||

| d | D | d1 | D1 | h | H | |||||

| AN01 | Φ25×40 | 0.7 | 0.45 | 24.5 | 40.5 | 22.5 | 38.0 | 40.0 | 49.0 | 20 |

| AN02 | Φ35×39 | 1.0 | 0.6 | 35.5 | 53.5 | 31.0 | 49.5 | 39.5 | 49.5 | 30 |

| AN03 | Φ38×55 | 1.1 | 0.7 | 38.5 | 56.5 | 32.5 | 54.5 | 55.0 | 65.0 | 50 |

| AN04 | Φ42×63 | 1.2 | 0.75 | 42.0 | 63.0 | 36.0 | 59.5 | 63.0 | 71.5 | 70 |

| AN05 | Φ52×70 | 1.5 | 0.95 | 52.5 | 74.0 | 48.5 | 70.5 | 70.0 | 80.0 | 130 |

| AN06 | Φ58×78 | 1.7 | 1.05 | 58.0 | 80.5 | 53.0 | 76.5 | 78.5 | 91.0 | 180 |

| AN07 | Φ70×87 | 2.0 | 1.25 | 70 | 94.5 | 65.5 | 90.0 | 87.0 | 99.0 | 300 |

| AN08 | Φ80×96 | 2.25 | 1.4 | 79.5 | 102.0 | 71.5 | 99.0 | 96.5 | 108.0 | 420 |

| AN09 | Φ90×104 | 2.5 | 1.55 | 89.5 | 115.5 | 81.5 | 110.5 | 104.5 | 120.0 | 580 |

| AN10 | Φ98×118 | 2.8 | 1.75 | 97.5 | 128.0 | 91.5 | 120.0 | 118.0 | 133.0 | 800 |

| AN11 | Φ120×201 | 3.15 | 1.95 | 102.5 | 128.5 | 89.5 | 116.5 | 201.5 | 215.0 | 1400 |

| AN12 | Φ120×130 | 3.2 | 2.0 | 118.5 | 155.0 | 112.5 | 148.5 | 130.5 | 150.5 | 1350 |