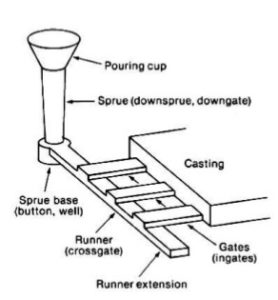

Down sprue – Pouring cup

At the top of the down sprue, a pouring cup (pouring basin) is often used to minimize splash and turbulence as the metal flows into the down sprue.

Pouring Cup is the funnel-shaped opening, made at the top of the mold. The main purpose of the pouring basin is to direct the flow of molten metal from ladle to the sprue.

The ceramic sprue tube for foundry has advantages of its high refractoriness, anti-scouring, light-weight and practical, easy-cutting and convenient for using, cost-saving and improving cast quality.

The product is suitable for resin sand, sodium silicate sand, precoated sand, and some other formative technology. It is used for casting high manganese steel, alloy steel, stainless steel, carbon steel, high chromium cast iron, ductile iron, grey iron castings, etc.

The appearance requirement and dimension allowable deviation for the ceramic sprue tube

| Item | Index error (mm) | |||

| Inner diameter | ﹤50 | Dimensional tolerance | ±2 | |

| 50-100 | ±3 | |||

| ﹥100 | ±4 | |||

| Length | ﹤300 | ±4 | ||

| ﹥300 | ±5 | |||

| Thickness | ﹤5 | ±2 | ||

| 5-10 | ±2 | |||

| 11-20 | ±3 | |||

| ﹥20 | ±3 | |||

| Inner diameter﹤ф50 | Ovality deviation | ±2 | ||

| Inner diameterф50-ф100 | ±3 | |||

| Inner diameter﹥ф100 | ±4 | |||

| melting hole | Non-critical area diameter | ﹤5 | ||

| Length﹤300 | Bend | ±5 | ||

| Length300-500 | ±6 | |||

Physical and Chemical Index of the HuaGuang’s Ceramic Sprue components

| Item | Proportion of Al2O3

% |

Fire Resistance

℃ |

0.2Mpa Refractoriness Under Load

℃ |

linear change on reheating

(1400℃.2h)% |

Show Porosity % | Cold Crushing Strength

Mpa |

Anti-Erosion Properties mm |

| Index | ≥45 | >1700 | ≥1280 | ﹢1

﹣2 |

≤30 | ≥30 | <1 |

Special technical requirements shall be determined by both parties.